Quick Patch®

Save time and money on repairs with Quick Patch®

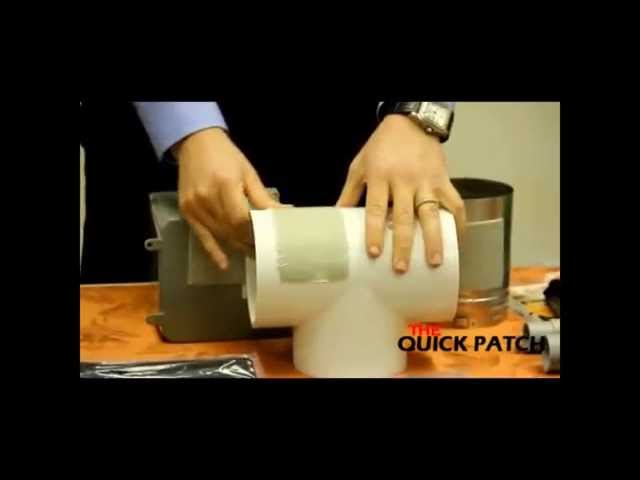

With Quick Patch repair patch you simply peel it and seal it. No special tools are needed!

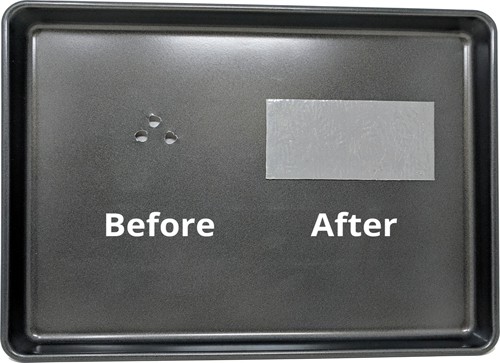

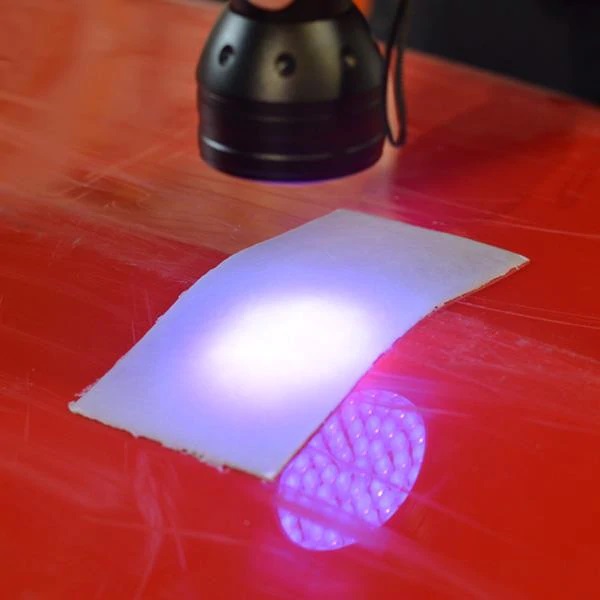

A one-of-a-kind unique product, Quick Patch comes out of the package as pliable as a Band-Aid. Ten minutes later with UV light it transforms into a hard patch that you can sand, paint or drill. The many uses you’ll find for this patch will save you time and money on many of your normally costly equipment repairs and fixes.

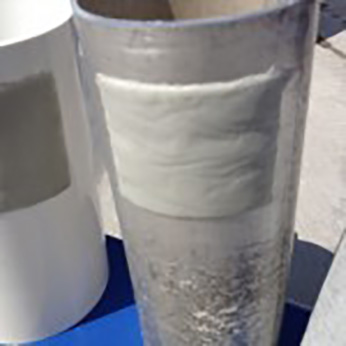

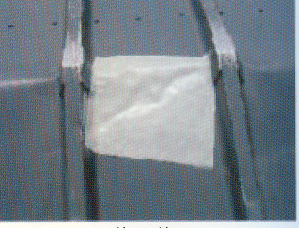

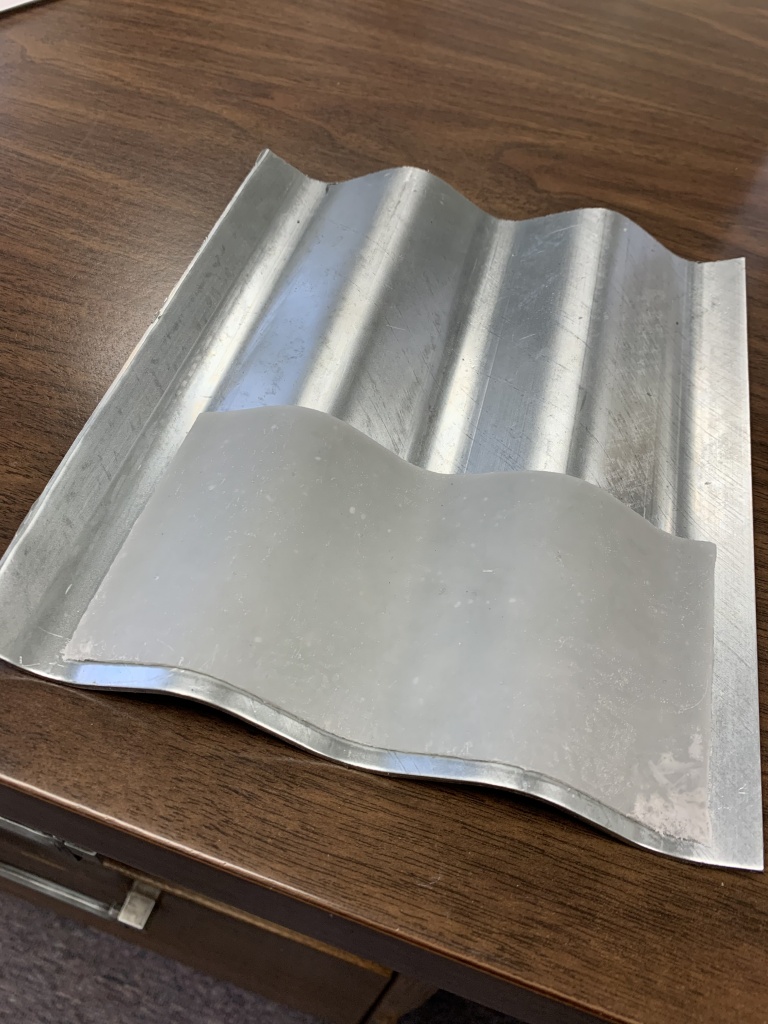

Quick Patch can be used on almost any hard surface such as piping, glass, ceramics, concrete, fiberglass, metal, wood, polyethylene and more. When using Quick Patch outdoors the sun cures the patch, indoors you’ll need a UV flashlight. Quick Patch cures rock hard, resistant against many chemicals, solvents and oils, is rot-proof, waterproof and is also impact resistant.

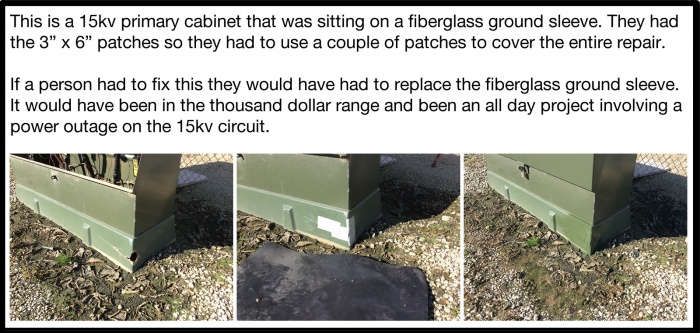

This patch is ideal for plumbers, farmers, mechanics, builders and many others. Quick Patch can be used to repair and maintenance roofs, steps, tanks, pipes, lines, gutters, switch boxes, bumpers, radiators, rusted areas, exhaust leaks, fuel tanks, boats, jet skis, canoes, and much more!

Non-flammable, non-toxic and the adhesive will not harm your skin. Quick Patch is fiberglass reinforced polyester with excellent adhesion properties for long lasting repairs.

Now available in Custom Sizes! Up to 3 feet wide and up to 30 feet long. Size possibilities are endless, minimum order quantities apply. Call Dick Simon for more information at 302-231-2624.

Applying Quick Patch Repair Patch is as easy as 1…2…3…

- Surface should be cleaned, dry and free of any contaminates. Cut Quick Patch into any size you want, without exposing to UV / Sunlight. Place remaining material back in protective bag.

- Remove white backing tape to expose the sticky resin. Apply Quick Patch to repair area with sticky side down and press firmly.

- Apply patch then remove transparent film backing on the other side after application and expose to UV or Sunlight. Curing time depends on UV intensity, between 5 minutes (sunny) and 50 minutes (cloudy) or use a UV light indoors with a minimum of 51 lumens.

Details:

- Easy application – just cut, peel and stick

- Flexible and Waterproof

- Weather and UV Resistant

- Temperature Resistant from -40°C to 200°C

- Extremely durable reinforced polyester/plastic

- Bonds to all hard surfaces except Polypropylene (PP)

- Can be drilled, tapped, sanded and painted in less than an hour

- No shrinkage or expansion during the application or after curing

- Fast curing (starting at 5 minutes depending on UV intensity)

- Curing Mechanism: Ultra Violet (UV), Natural or UV Lamp

- Fire rating Class 1

- Dielectric strength 9 kV/mm, Arc resistance > 180 sec., Tracking resistance > 600 V and Insulation resistance 10 to the power of 13 ohms

Applications:

- Industry: Repair and maintenance roofs, steps, tanks, pipes, lines, gutters, switch boxes, etc.

- Automotive, Truck & Transport: Bumpers, radiators, rusted areas, exhaust leaks, fuel tanks and lines, box bodies, headlamp housings, all kinds of plastics and body components

- Hobby/Sport/DIY: Jet skis, canoes, boots, surf boards, prototyping, modeling, windows, doors, fences, roofs, drainage lines, pools, spas, garden equipment, sanitation systems, bail tanks and lines, sporting equipment and various other surfaces like GRP, wood, metal, glass, ceramics, concrete and plastics

Looking to purchase Quick Patch retail online? Check out http://buyquickpatch.com

Click on images to enlarge.

Resellers please feel free to download any of these pictures for marketing purposes.

Click on any video thumbnail to watch.

Download the Unbranded Patch Video to use for Private Label Patches

Is Quick Patch harmful to skin?

Quick Patch is a non-hazardous material, however, it is recommended that anyone with sensitive skin should wear appropriate protective gloves when handling the material. Full Health & Safety information available in the Safety Data Sheet available for download on our website.

Can multiple layers be applied?

Yes, multiple layers can be applied, however, we would not recommend anymore than five layers to be applied at any one time. When adding layers additional curing time should be allowed in order for each layer to fully cure.

What sizes are Quick Patch available in?

Standard sizes are 3″ x 6″, 6″ x 9″ and 9″ x 12″. Additional sizes can be manufactured.

Is preparation of a surface required?

No, surfaces only need to be clean, dry and free of any loose contaminants.

Can Quick Patch be used on wet surfaces?

No, it is not recommended to use the patch on wet surfaces. But Quick Patch Extreme works on wet surfaces and underwater. Quick Patch Extreme is our Quick Patch with no tape, and my glue sold as a kit. It’s perfect for wet and underwater applications!

Can Quick Patch be returned to the original pouch?

Yes it can. It is recommended that any unused portion be returned to the original packaging for storage purposes.

Will Quick Patch stick to any surface?

Quick Patch will bond powerfully to most clean and dry surfaces. It is not recommended to use Quick Patch on Polypropylene or bituminous surfaces.

What is the shelf life of an unopened Quick Patch?

24 months from Date of Manufacture.

What can I do with Quick Patch after it has cured?

Quick Patch can be drilled, tapped, sanded and painted in less than hour (depending on cure time needed).

How do I apply Quick Patch?

- Surface should be cleaned, dry and free of any contaminates.

- Remove from protective bag. Cut Quick Patch to any size you need without exposing to UV/Sunlight. Place remaining material back in protective bag.

- Remove white backing tape to expose the sticky resin.

- Apply Quick Patch to repair area with sticky side down. Press firmly and expose to UV/Sunlight.

- Remove transparent film backing from other side after application.

- Curing time depends on UV intensity – between 5 minutes (sunny) and 50 minutes (cloudy).

How do I cure Quick Patch?

Quick Patch can be cured outdoors by just the sun, even on cloudy days (will take longer to cure on cloudy days), indoors you can use a UV light that is a minimum of 51 lumens.

What items can Quick Patch be used on?

Boats, personal watercraft, engine parts, decking, fenders, gas cans, gutters, water tanks, PVC pipes, all kinds of plastics (except polypropylene), plexiglass, fiberglass, metal, wood, concrete, switch boxes, box pads, ground sleeves, riser poles, radiators, rusted areas, exhaust leaks, fuel tanks and lines, trailers, cargo containers, headlamp housing, auto body components, jet skis, canoes, surf boards, fences, roofs, drainage lines, pools and spas, garden equipment, sanitation systems, swim platforms, baitwells, glass, and ceramics.

What is Quick Patch made of?

Quick Patch is a made of a fiberglass reinforced polyester.

Will Quick Patch shrink or expand during application or after curing?

No, Quick Patch will not shrink or expand either during application or after it has cured.

What temperatures will Quick Patch withstand?

Quick Patch is temperature resistant from -40° C to 200° C.

Is Quick Patch waterproof?

Yes, it is! It is also Weather and UV Resistant too.

How long does the Quick Patch take to cure?

Between 5 minutes (sunny) and 50 minutes (cloudy) or use a 51 lumens UV light indoors.

What tools do I need to apply Quick Patch?

No tools are needed, but can cut the patch to a smaller size with scissors or a knife if you need to. If you’re applying Quick Patch indoors you will need a UV light ( ask about our UV Flashlight!) with 51 lumens.

What are the technical data details for Quick Patch?

Appearance: Sheet Lamination

Color: Grey

Curing Mechanism: Ultra Violet (UV), Natural or UV Lamp

Material Thickness: 1.0-7.5 mm.

Weight: 2.9 kg/m2

Tensile strength: > 55 MPa (Test Method: BS 2782 bis 1994)

Flexural strength: >130 MPa (Test Method: ASTM D 790-03)

Flexural modulus: >5,98 MPa (Test Method: ASTM D 2344)

Elongation at break: >3% (Test Method: BS 2782 bis 1994)

Coeff. of thermal expansion: 2,9010-5K-1 (Test Method: ASTM D 696-03)

Impact Resistance: >60 kJ/m2 (Test Method: BS EN ISO 180)

Hardness: >60 Barcol (Test Method: ASTM D 2583)

Compressive strengh: >200 MPa (Test Method: ASTM D 695-2002)

Adhesion to C-steel: >14 MPa (Test Method: ASTM D4541-02)

Water vapour permeability: 0,28 g/m2/24h/mmHg (Test Method: ASTM E 96)

Heat distortion: >145°C (Test Method: ASTM D 648)

Fire rating: Class 1 (Test Method: BS 476 pt7:1997 ASTM 84)

Flash point: >32°C (Test Method: ASTM D 93)

Dielectric strength: 9 kV/mm (Test Method: IEC 243)

Arc resistance: >180 sec. (Test Method: ASTM D 495)

Tracking resistance: >600 V (Test Method: IEC 112)

Insulation resistance: 10 to the power of 13 ohms (Test Method: IEC 93)

Heat Resistance: Wet – 90° C Dry – 200° C

Chemical resistance: Good. Chemical resistance chart available upon request.

Working life: Vigilant care should be taken to keep Quick Patch from direct sunlight or UV lamps during application as this will greatly reduce the working life of the material during application.

Environment: Under no circumstances should Quick Patch be applied in wet conditions or on wet substrates.

Safety Precautions: Please refer the product Material Safety Data Sheet for detailed information on handling and disposal.

Storage: Prior to use store in cool, dry conditions (not more than 25° C) prior to use. Avoid storage near any heat source or sunlight. Always store material in its original packaging in a horizontal position. Boxed material should be rotated 180° every 30 days for optimum condition.

Shelf Life: 12 months when stored per manufacturer’s instructions.

All guidelines, recommendations, statements, and technical data contained herein are based on information and tests we believe to be reliable and correct, but accuracy and completeness of said tests are not guaranteed and are not be construed as a warranty, either expressed or implied. It is the user’s responsibility to satisfy their-self with their own testing to determine suitability of the product for intended use, application and job situation. User assumes all risk and liability resulting from use of the product. We do not suggest or guarantee that any hazard listed here in is the only one which may exist. Neither seller, nor manufacturer shall be liable to the buyer or any third person for any injury, loss or damage directly or indirectly resulting from use at, or inability to use the product. Recommendations or statements, whether in writing or oral, other than those contained herein, are not binding upon the manufacturer unless in writing and signed by a corporate officer of the manufacturer. Technical and application information is provided for the purpose of establishing a general profile of the material and proper application techniques. Test performance results were obtained in a controlled environment and Bullseye Products LLC makes no claim that these tests or any other tests accurately represent all environments.

- HVAC – Condensate Pan & Drain Repairs, Duct Repairs

- Bowling Alleys – Repair of bowling alley equipment

- Cooling Towers

- Wheelbarrows, Buggies and Pushcarts

- Outdoor / Patio Furniture

- Pipelines

- Construction – repairs and equipment repairs

- Auto – Exhaust, fuel tank, box body, radiator, bumper repairs

- Boat & Marine

- Cargo & Freight

- Electrical

- Hotels & Motels

- Irrigation

- Machinery

- Plumbing

- Pools & Spas

- Solar

- Snow Removal Equipment

- Roofing

- Sheet Metal

- Tractor

- Trucks & Trailers

- Utilities –Woodpecker & Boring Insect repairs on distribution poles and more!

- Tanks

- Water Parks

- RVs & Trailers